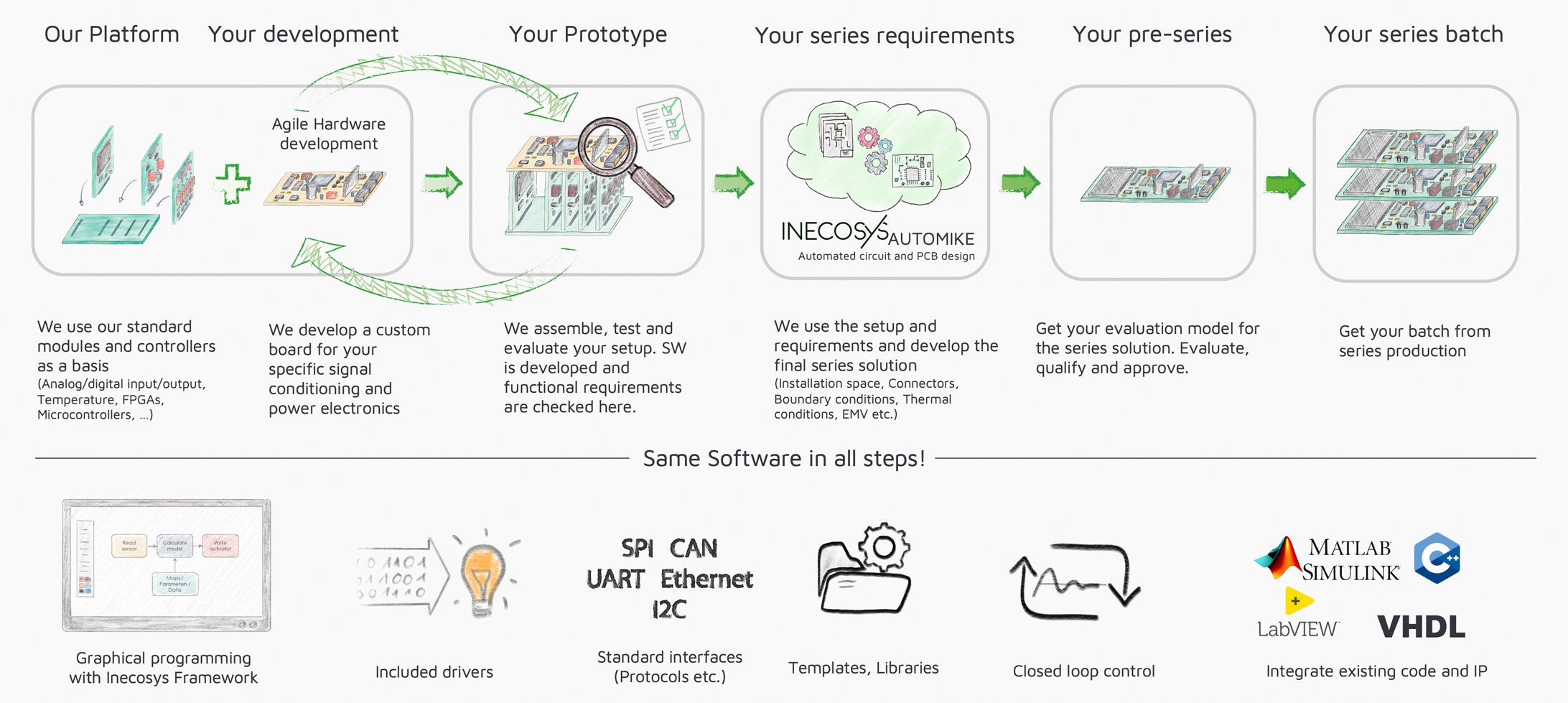

WHAT IS RAPID SERIES DEVELOPMENT?

Rapid Prototyping is widely used in industry to get fast results in an early stage of development. But what is the next step? The transfer of the gained knowledge into a series product is usually carried out manually by creating a following series development project. Obviously, this approach is quite static, arduous and not compatible with agile development strategies. To close this gap we created a process which automates this work and thus seamlessly integrates the complete development chain from prototype to series product. We use our process to provide you agile electronics development by reduces time and costs.

YOUR ADVANTAGES

- Reduce your time-to-market significantly. Your development and non-recurring-engineering costs will decrease, your risk will be lower.

- Master challenges like unclear specifications at the beginning of your projects or changing requirements during your projects. Start with leveraging agile electronics development.

- Remove interface problems and know-how barriers between involved developers. This will result in a more flexible and faster execution of your embedded project.

- Use one single development solution from the pre-development stage to the production stage!

- Flexible prototyping for both software and electronics (you can focus on creating the specific solution for your application).

- Fast transfer of the prototype to the series product (you only have to take care to series-specific issues like packaging, thermal requirements, EMV, functional coverage).

- Easy adaption and maintenance of the products even in the field.

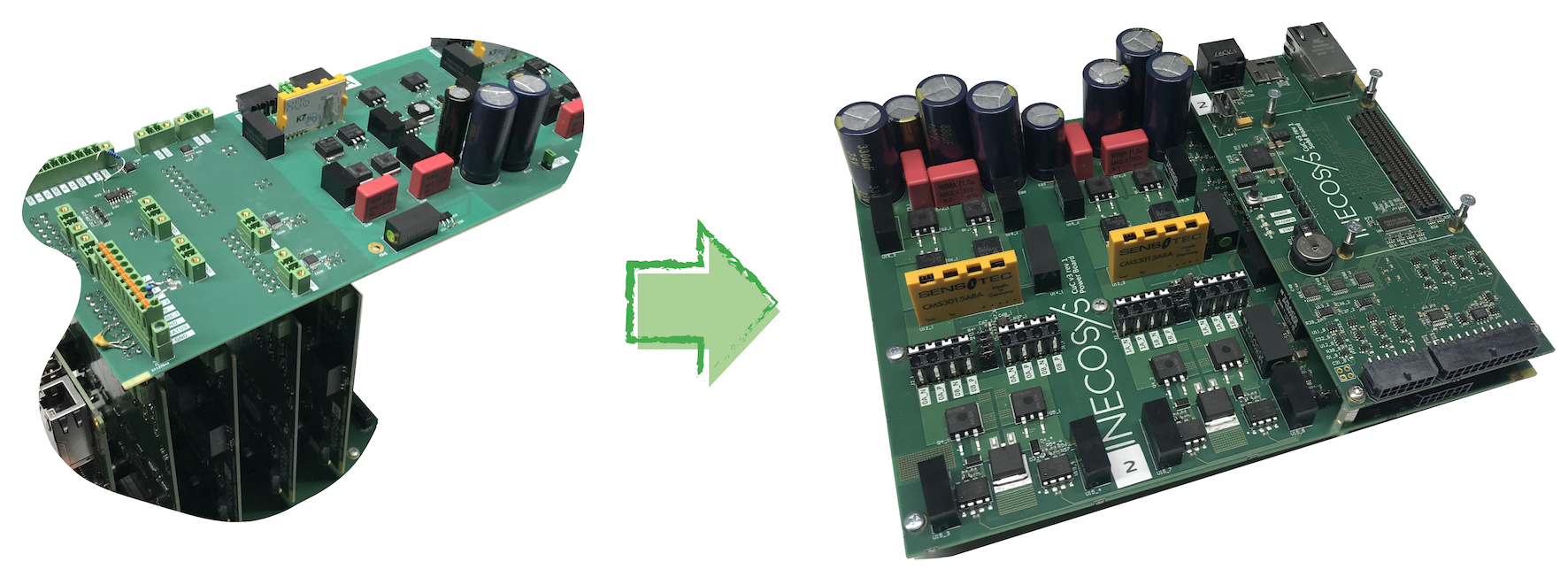

Example solution

- The last version of our CUC solenoid test system was developed by usind our RSD prototyping system with an attached custom board for power electronics.

- After finalizing all HW and SW development we used our algorithm to derive a monolithic PCB board

Assembled RSD platform with custom board

With our process generated Monolithic PCB